How many of you have hit a roadblock in this hobby, coming face to face with a task that needed to be done and you didn't have the confidence or skill to confront it head on and Just Do It? For some, it's benchwork - and they never even start a layout, contenting themselves with being "armchair modelers" and dreaming about "someday" when they'll build a layout - as if reading Just One More Article will magically endow them with the tools & skills they need. Heck, the same thing can be said about so many aspects of the hobby, whether it's electrical work, trackwork, structure building, or - in my case - scenery.

But if I've resolved anything for this hobby in the New Year, it's to confront this obstacle head on. I've been lucky enough to have some early success - and even luckier to have friends that have helped me along the way (e.g. less than 1/2 of the finished scenery on the layout was actually done by me). Having others help you - or actually do the work for you - while wonderful, does little to nothing to help you build YOUR skill and proficiency.

You just have to do it yourself - and try, try again if at first you don't succeed.

Fortunately, I'm here to share one of the rare times when a seemingly-insurmountable scenery obstacle actually turned out to be No Big Deal.

I'm talking about rock coloring.

Before yesterday, I'd never colored any rock castings & the only ones on the layout were done by others. But modeling a line set in Southern New England pretty much guarantees that I have to figure out how to do rocks at some point. So, now that I'm working in Dividend and will be modeling a railroad cut through a hill, it was high time to figure out how to do it.

|

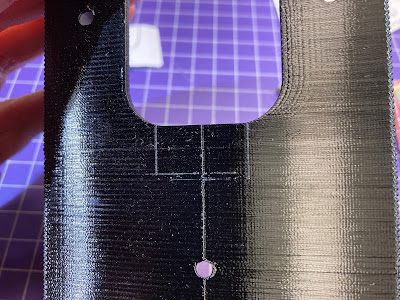

| Bare castings |

I'd made some rock castings some months ago - a pretty easy process, all things considered - but they'd sat for months in the glaring white of new plaster. So, figuring I had a bunch of "extras" to practice on, I did some quick research in my extensive library of scenery books and got to it.

|

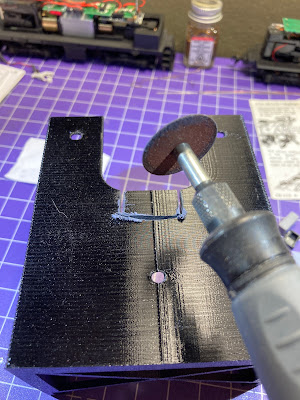

| The same castings, now colored |

In the process I discovered a technique for coloring rocks that's ridiculously simple and produces rocks that look very similar to what I see along my RR ROW everyday. I've only been coloring rocks for 2 days, so I'm certainly no expert - but I hope by sharing this super-easy technique that you'll be encouraged to try coloring some rocks too. It really is as easy as 1-2-3.

|

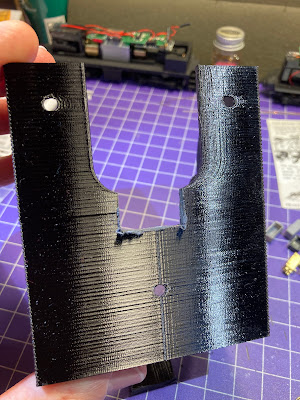

| The same castings once all dry |

But first, you'll need some materials.

- 3 Colors of Acrylic Craft Paint

- I used Raw Sienna, Raw Umber, and Black ($.50 ea at Walmart)

- Water

- Regular tap water is fine

- Brush

- I used a 1/4" wide cheap china brush

- Small Dixie Cups

- Bonus if they're plastic, so you don't have to worry about them getting soggy

- Medicine dosage cup

- Optional - I have plenty on-hand and the measurement markings are handy

- Stirring stick

Preparation

- Measure out 1 tablespoon of water, and pour it into one of your cups.

- Put 20 drops of Raw Sienna in the cup and mix it by stirring thoroughly

- Measure out another tablespoon of water, and pour it into your second cup.

- Put 20 drops of Raw Umber in the cup and mix it by stirring thoroughly.

- Measure out a final tablespoon of water, and pour it into your final cup.

- Put 7 drops of Black in the cup and mix it by stirring thoroughly.

Here's what you should have when you're done - 3 cups of very thin paint which we'll use to "wash" over the rock casting:

|

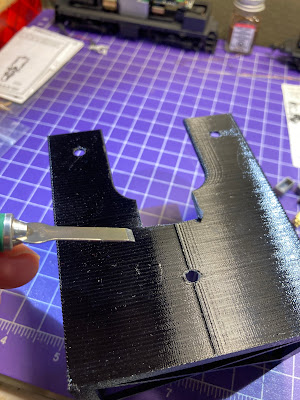

| Here's the rock casting I started with - all nice and white plaster, but doesn't look like a rock. |

Step 1 - Brush on Raw Sienna

Literally, just dip your brush in the cup of Raw Sienna wash and brush it all over the casting. If you get any pooled wash, just wipe your brush off on a paper towel and use the brush to daub up the puddle. When you're done, the casting will look like this:

Before you go to the next step, you need to let the casting dry. Acrylics dry relatively fast, but if you're impatient like me, you can use your wife's a hairdryer you bought just for such things to blow dry the casting much faster. Here it is once it's all dry:

Step 2 - Brush on Raw Umber

Yup - same "technique" - just dip your brush in the cup of Raw Umber wash and brush it all over the casting, using your brush to daub up any pooling as I described above. Here's the casting right after applying the Raw Umber wash:

And here it is after blow-drying:

Step 3 - Brush on Black

Can you guess what comes next? RIGHT! Just dip your brush in the cup of Black wash and brush it all over the casting, daubing up any pooling. The black really makes things start to pop. Here it is semi-wet:

And -

voila! - here it is after blow-drying:

That is really all there is to it! Compare this "rock" to the stark-white plaster casting we started with. There's really no comparison. All of the variations of color really bring out the texture and make it look authentic. And, interestingly, different castings also take the colors a bit differently (as does different types and ages of plaster, apparently).

All that's left to do on this rock to is to weather it (if desired), maybe do some drybrushing to create more highlights, add some "mosses" and other vegetation (ground foam, etc), and - of course - place it on the layout. . . probably somewhere near the front, where such a wonderful bit of modeling can be seen and enjoyed.

I'm almost embarrassed to admit how long I'd put off coloring rocks - you can bet I would've tried it sooner if I'd realized it'd be this easy to do. Of course, this is just one technique - there are certainly others out there and you can play around with different colors to suit the locale you're modeling.

I hope seeing how crazy easy rock coloring is will encourage you to try it for yourself. And if you do, I hope you'll let us know and share your results with us in the comments below.

Happy Modeling & Rock On!*

*sorry - you didn't really think I could resist, did you?