The photo above shows where things sit in Deep River since

my last update there... As mentioned, this is just base scenery (dirt & ground foam) for now, along with a mockup of the photo backdrop showing the Connecticut River, shot at the prototype location.

Since getting to this point, I've had an open house in conjunction with the

NHRHTA's annual reunion, as well as an op session. I may do posts about those events at some point, but the main thing to report here that resulted from NHRHTA weekend was the return of the #3016 from the shop!

The photo above shows her having just arrived at Essex (which reminds me - I gotta get some more scenery done here!)

I also received a nicely-done reefer from my friend DonM, which I show above at Ballantine's in Wethersfield, having just delivered some product.

As wonderful as those new (and not so new) acquisitions are though, the main focus of this post is on two quick projects that were prompted by my most recent op session.

|

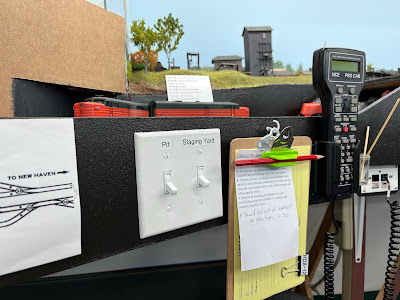

| Ever since the layout was operational, the power and command station switches have been located on the fascia at Middletown. |

|

| Unfortunately, for some reason during this last session, they got bumped - not once but twice! - during the session, shutting down the entire railroad! Something had to be done . . . |

The crew made many suggestions, including moving the switches, recessing them, etc. I thought boxing around them would be the easiest thing to do - especially since the aisle here is by far the widest one I have, so no concern with something sticking out too far (except power and command station switches, apparently!)

Not wanting to go to the trouble of building a box (or moving or recessing the switches), I searched around for something suitable. And found this . . .

|

| This is an old cufflinks box I found in the attic. Turns out, it's perfect for my purpose. . . |

|

| I used scrap paper to make a cutting template, then used spade bits to do the actual cutting (a vise held the box during cutting...) |

|

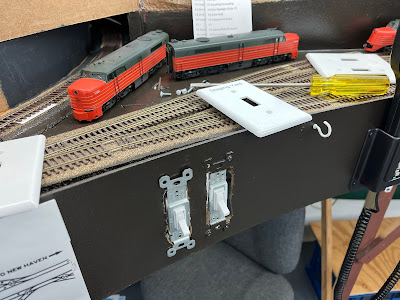

| And here it is in place! |

Another issue that's become more and more apparent lately, especially as I power up the layout for testing, op setup, etc., is that I have too many engines starting up, doing nothing. I'd previously cut out all of New Haven staging and 1/2 of New London staging, so engines stored there only power up when I turn those particular tracks on.

But in "Somerset" (the supposed south end of the Airline Branch) and Middletown, engines are typically stored there too. So it was high time to have a way to turn off those storage tracks. . .

|

| I started in Middletown. There's one stub-end yard track there that I often use to store & display power - but there's no good reason to have engines just sitting there idling if they're not needed. The first step was to see if a regular wall switch would fit where I wanted it... |

|

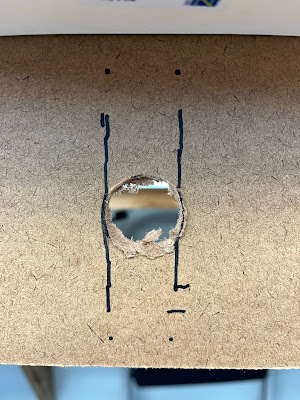

| Once I marked the hole location, I used a 1" spade bit to cut the first hole, centered. |

|

| That allowed me to insert the switch far enough to trace around it . . . |

|

| And I used the outline to guide the cutting of the other two holes, as well as where to drill pilot holes for the mounting screws. |

|

| The steamer is sitting on the unpowered stub track. Not wanting to have to construct (or find!) another box to protect this switch from being bumped, I just located it under the bill box for Middletown. |

|

| Should be pretty safe here... "should" be... |

|

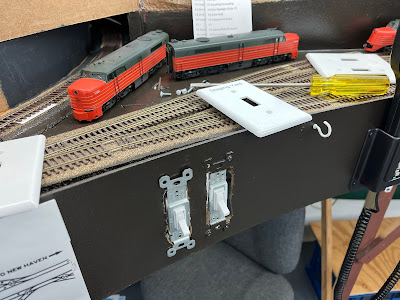

| Next, I turned my attention to Somerset. The easiest location for the switch was to put it right next to the switch for New Haven staging. |

|

| Same process, except this time I used a double-gang faceplate to make sure I put the 2nd switch in the right location. |

|

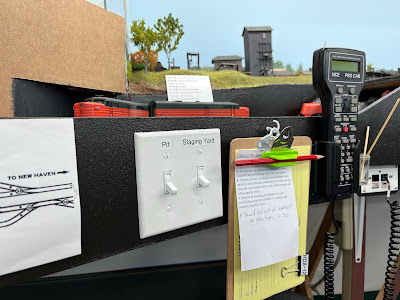

| And here it is installed. The "Pit" is the stub ended track otherwise known as the engine service track, located where you see the coaling tower in the pic above. |

|

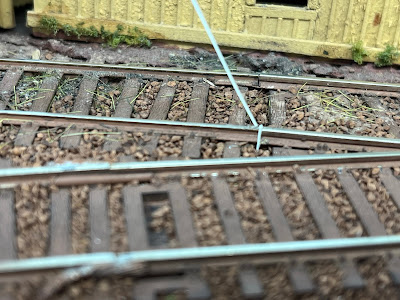

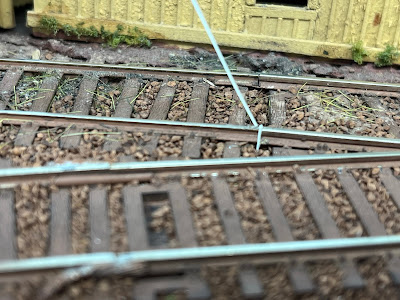

| Unlike the stub track in Middletown, which branches off using a Micro-Engineering turnout (and thus already had an insulating gap - I only had to reroute the feeder wire to the switch and back), I needed to cut a gap into one of the rails on the pit track. A razor saw made quick work of it, without creating too wide a gap. But I needed to fill the gap with some styrene strip (HO scale 1x3) ACC'd in place. |

Before we go, since we're in Somerset already anyway, let's check out #3016 that's just arrived with a local it needs to switch out . . .

Here's hoping you and yours have a wonderful weekend - and get lots done on your projects!