As we continue building the "Bethel Camp Cottages" (click here for part 1, here for part 2, and here for part 3), it occurred to me . . .

. . . Other than its overall proportions, the other thing I liked about the house I borrowed from Somerset as my temporary stand-in (pictured above) was the little porch.

Unfortunately, while the gable trim on the house kits I'm using is great and really evokes the "camp cottage" look I'm going for, they don't have any sort of porch. So I got the bright idea of using the floor and roof parts from the lean-to addition provided in the kits to build some back porches. Having a back porch rather than a front porch may seem a bit odd, but since the cottages face away from the Connecticut River, I figured a rear porch would give my little camp denizens a nice place to have a cup of coffee and enjoy the view.

Unfortunately, the lean-to parts are a bit too wide, so I had to narrow the floor and the roof.

And in a bit of overkill, I reached out to my friend ScottL, who is a professional home builder (among many other talents) and he sent me this handy - and very detailed - diagram on how to build the porch.

In the end, I ended up doing a lot of eyeballing...

You can see in the photo above how I shortened/narrowed the lean-to floor by about 6 boards. The front porches included in the kit are actually just little stoops, so I used the 6 boards I'd removed from the lean-to floor to create a larger front porch, as you see with the house on the right.

I also narrowed the porch roofs by about 1/4" to match the width of the porch (which, in turn, matches the width of the cottage).

Using Scott's blueprint as a guide, I realized that the depth of the porch roof would need to be reduced as well, or else the roof would have WAY too much overhang. Coincidentally, I removed about 6 courses/rows of shingles to get a depth that looked right. Thankfully, these seams - which actually aren't too prominent - will be totally hidden by the roofing material I'll add later.

To give the porch roof a bit more strength & stability, I added a ledger board to the back wall of each cottage using "2x4" strip styrene, glued right on the highest clapboard before the clapboards start to narrow. The rear edge of the roof will rest on this, just like the prototype.

While I could have just used 4x4 strip styrene for the porch posts, I dug through my Tichy assortment box and came up with exactly the number of posts I needed for the three cottages (6). These are Tichy #8092, shortened about 1/8" in order to allow the roof to pitch down.

|

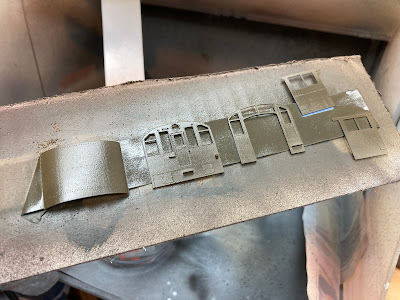

| Here are all the parts, ready for assembly (including a porch roof section that still has to be narrowed). |

|

| And here it is added to the cottage. |

Once I showed this photo around, some folks pointed out that the roof looked a bit thin - like it needed a bit more structure.

So, instead of actually doing individual rafters, I decided to simulate them by just adding fascia board around the perimeter of the roof. I think you'll agree it looks much more realistic this way.

The last step on the roof was to paint the fascia boards to match the trim color. Believe it or not, especially considering

my historic fear of airbrushing, I masked off the fascia boards and

airbrushed them to match the rest of the trim.

With that done, all that's left to do is the roofing material itself and final painting and these cottages are within striking distance of being finished! Check in next time as we wrap up this build . . .